Introducing the Intricacies of Next-Generation Power Units: a Deep Study Advanced Engine Innovations and designs

As we stand on the precipice of a new period in transportation, the details of next-generation engine styles bid us to explore the sophisticated innovations and technologies that guarantee to redefine the driving experience. Diving deeper right into the realms of discharge control, smart engine management systems, and the perspective of power unit advancement, we locate ourselves on the cusp of a change that guarantees to improve the landscape of movement as we understand it.

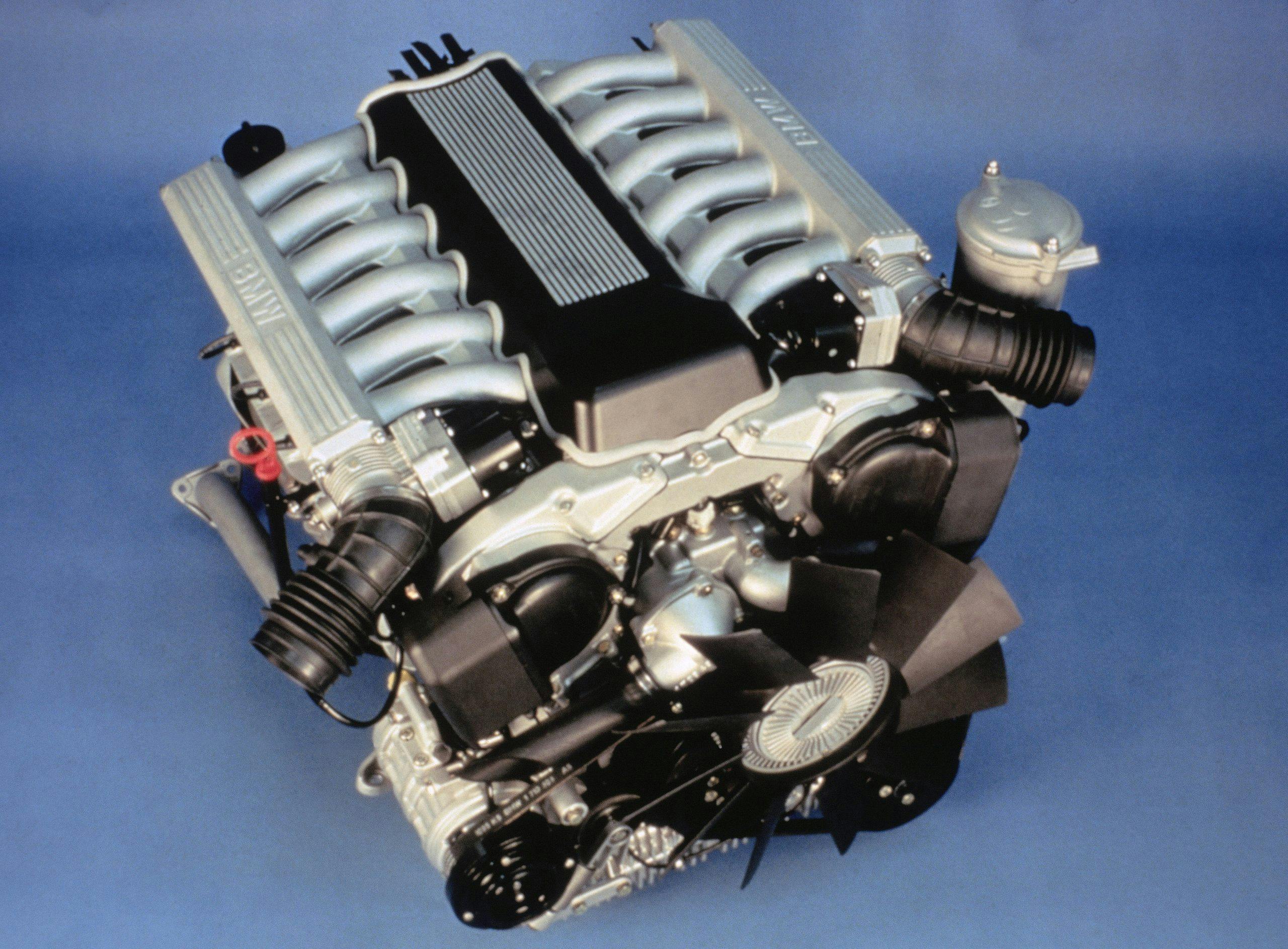

Development of Engine Materials

The shift in the direction of advanced engine materials has likewise made it possible for engineers to create engines with higher power outcomes while keeping gas efficiency criteria. For instance, using light-weight materials reduces the general weight of the engine, bring about boosted gas economic situation and reduced emissions. Furthermore, improvements in products modern technology have actually permitted far better thermal monitoring within engines, causing raised reliability and longevity.

Turbocharging and Supercharging Technologies

How do Turbocharging and Supercharging Technologies revolutionize engine efficiency and performance in modern-day automobiles? Turbo charging and turbocharging are modern technologies that considerably enhance engine performance by boosting the amount of air consumption into the burning chamber. Turbocharging attains this by using a turbine driven by exhaust gases to pressurize the consumption air, while supercharging makes use of a belt- or chain-driven compressor to accomplish the very same effect.

These technologies make it possible for smaller sized, more fuel-efficient engines to generate power equivalent to bigger ones, known as downsizing. By requiring even more air into the cyndrical tubes, turbocharging and turbo charging improve combustion performance, leading to raised horse power and torque output without a substantial increase in engine dimension. This leads to much better velocity, hauling ability, and total driving performance.

Additionally, turbocharging and supercharging add to improved fuel performance by allowing the use of smaller sized engines that eat less fuel under regular driving problems - bmw engine. This combination of improved efficiency and performance has made turbocharging and supercharging important components of numerous contemporary engine layouts

Exhaust Control and Environmental Impact

With enhancing worldwide problems regarding air high quality and environmental sustainability, the application of exhaust control modern technologies in vehicles plays a vital duty in lowering harmful pollutants released into the atmosphere. Modern cars are furnished with innovative emission control systems that aid minimize the ecological influence of automotive procedures. Catalytic converters, for example, are made to transform poisonous gases such as carbon monoxide gas, view publisher site nitrogen oxides, and hydrocarbons into less harmful substances like carbon dioxide and water vapor.

In addition, innovations in engine modern technology, such as the assimilation of exhaust gas recirculation systems and careful catalytic reduction, have considerably contributed to decreasing exhausts. These modern technologies operate in tandem to optimize combustion performance and lessen the release of hazardous toxins into the air. In addition, the growth of hybrid and electric lorries stands for an important step in the direction of minimizing the general environmental impact of the transportation sector.

Intelligent Engine Monitoring Solution

Furthermore, these systems make it possible for cars to fulfill rigid discharges standards without endangering performance, giving a more eco-friendly driving experience. The integration of synthetic knowledge and device understanding capabilities in engine management systems remains to push the borders of what is possible, resulting in additional renovations in effectiveness, integrity, and overall automobile performance. bmw engine. As automotive innovation advances, intelligent engine monitoring systems will certainly play a vital duty fit the future of transport in the direction of a more reliable and lasting direction

Future Trends in Power System Advancement

As smart engine monitoring systems lead the method for improved control and optimization in contemporary cars, future patterns in power unit development are poised to redefine the landscape of automotive propulsion modern technologies. These different power resources use enhanced efficiency and performance while straightening with rigorous ecological policies.

Another significant fad is the combination of sophisticated materials and making methods. Lightweight materials such as carbon fiber and light weight aluminum are being used to decrease total automobile weight, improving fuel performance and performance. Additionally, advancements in 3D printing and additive manufacturing are enabling the manufacturing of complicated engine components with higher accuracy and longevity.

In addition, expert system and machine knowing are playing a critical role in maximizing power unit efficiency. These technologies permit for real-time tracking and flexible control, resulting in more trusted and effective power distribution. In general, future fads in power unit growth are geared towards sustainability, performance, and performance, driving the vehicle industry towards a new era of propulsion modern technologies.

Final Thought

Finally, the innovations in engine products, turbocharging, exhaust control, and intelligent monitoring systems have led the way for next-generation power systems. These innovations have not just improved performance web and performance but likewise reduced environmental influence. As technology remains to advance, future patterns in power device development view it now are likely to concentrate on more enhancing sustainability and enhancing power result. The intricate styles and technologies in modern engines showcase the continuous advancement of automotive innovation.

Exploring the progressive developments in engine materials has been critical in improving the efficiency and effectiveness of contemporary engines. Over the years, the development of engine products has actually played a critical duty in pressing the borders of what engines can attain.The shift in the direction of progressed engine products has actually likewise allowed engineers to develop engines with higher power outputs while maintaining fuel efficiency criteria.The execution of smart engine administration systems in contemporary cars has revolutionized the way engines are regulated and maximized for efficiency and effectiveness. By collecting information in real-time and assessing it with innovative formulas, smart engine management systems can adjust to driving styles, ecological elements, and engine health to maximize power outcome while reducing fuel intake and discharges.